Low speed

Medium speed

High speed

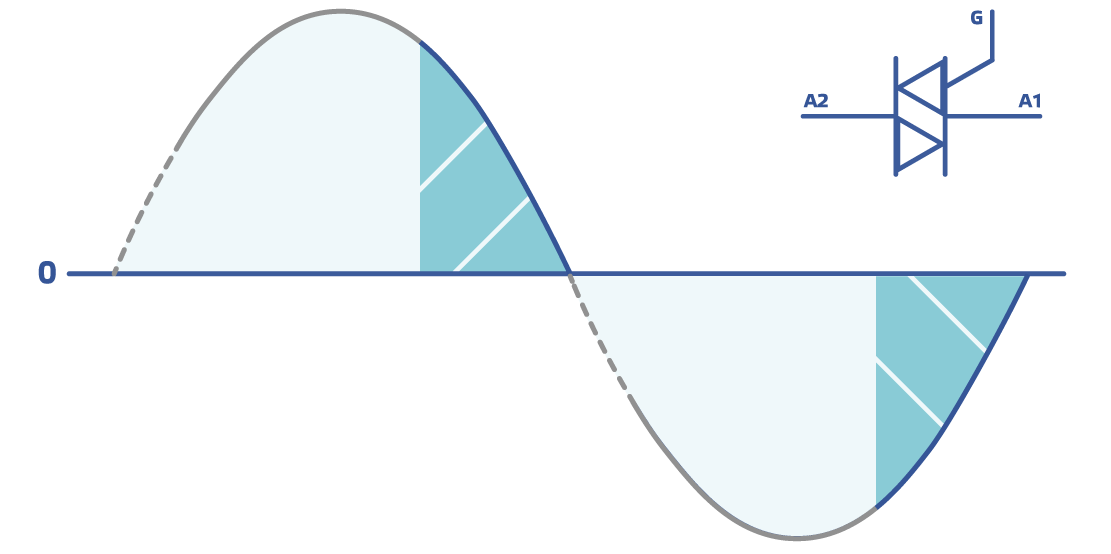

Transformer fan speed controllers

Transformer fan speed controllers control the speed of electric motors in steps. This stepped speed control is caused by the autotransformer technology they are built on, hence the name transformer. Thanks to this technology, they generate a motor voltage with a perfect sinusoidal shape. This results in an exceptionally quiet motor operation and an extended service life.

Autotransformers are electrical transformers with a single coil. Their different voltage taps enable reduced voltages. A special impregnated coating reduces the electrical noise from the autotransformers. However, the typical humming noise caused by the transformer technology might be noticeable in more quiet surroundings.

Transformer fan speed controllers are cost efficient and have proven to be very reliable and robust. They can also be used when there is an unstable power supply.

These fan speed controllers are easy to install. They don’t require any configuration. Some transformer fan speed controllers have an integrated rotary switch to manually adjust the fan speed. Other variants can be controlled remotely via Modbus RTU or via an analog control signal.

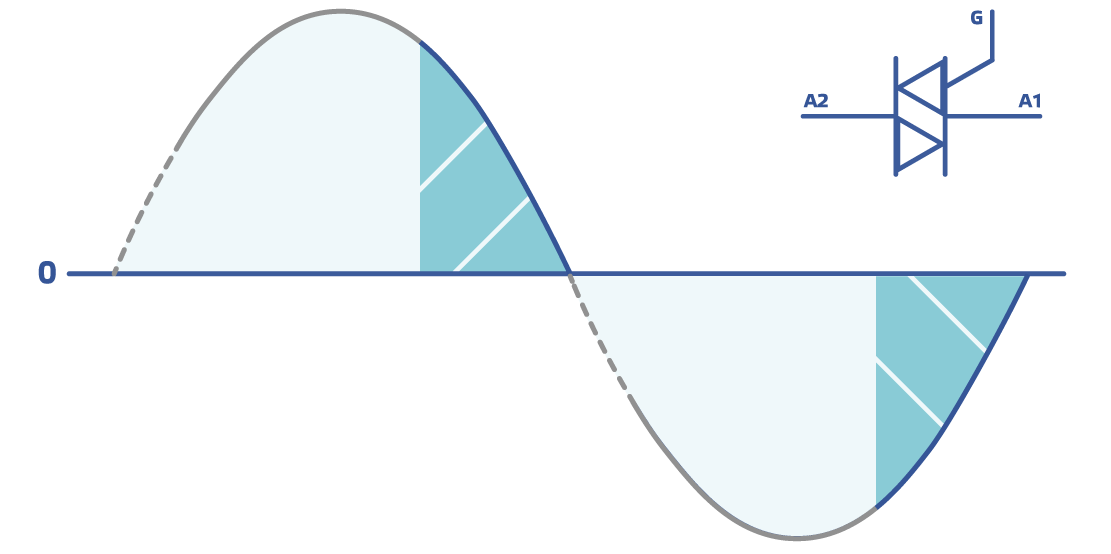

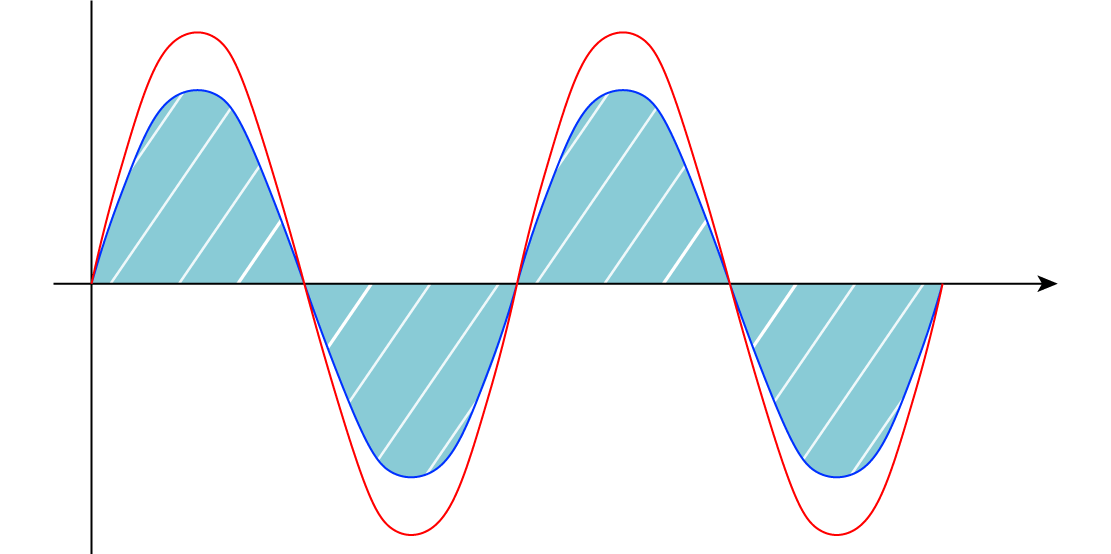

Electronic fan speed controllers

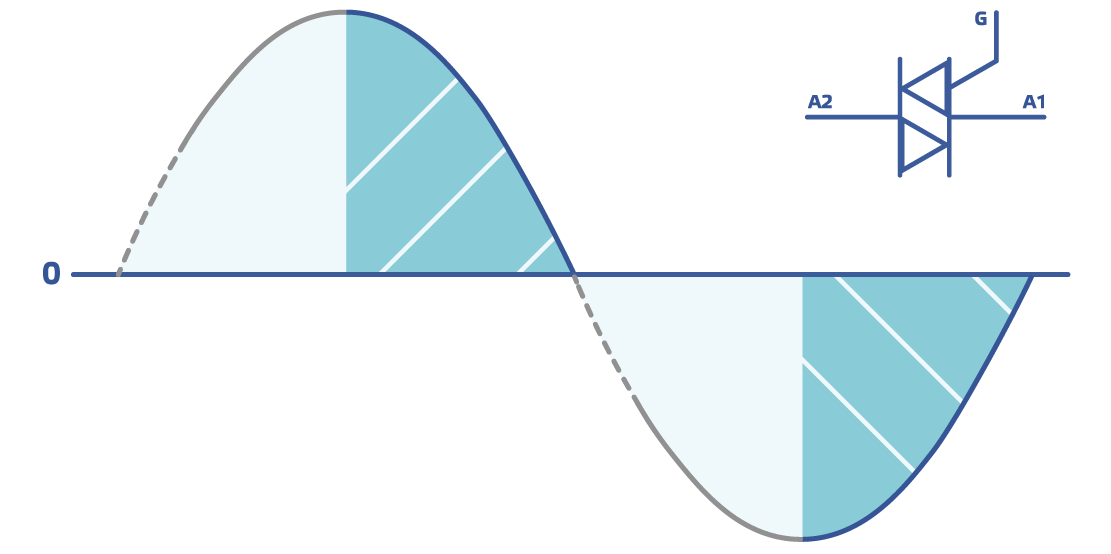

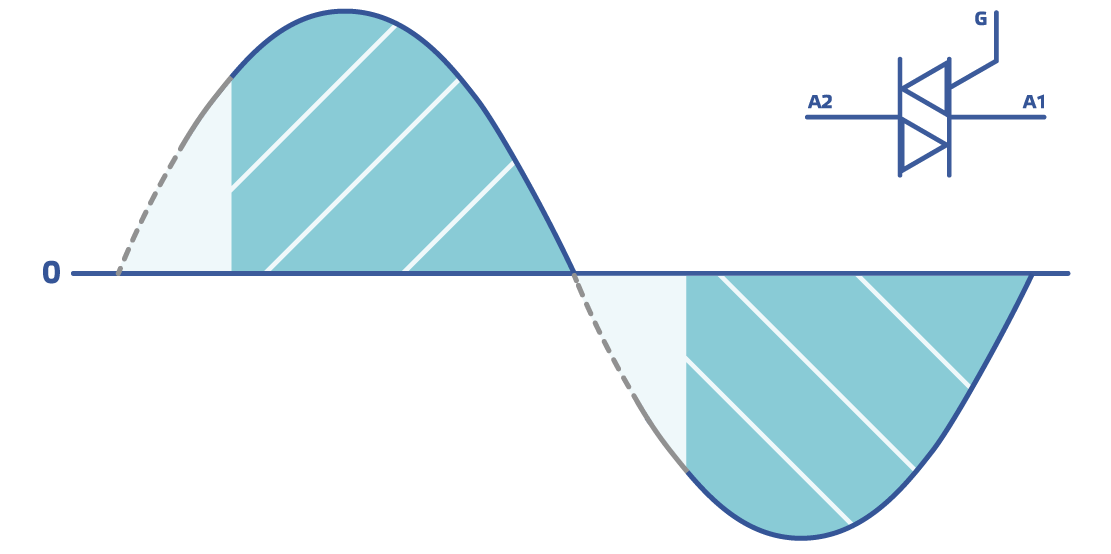

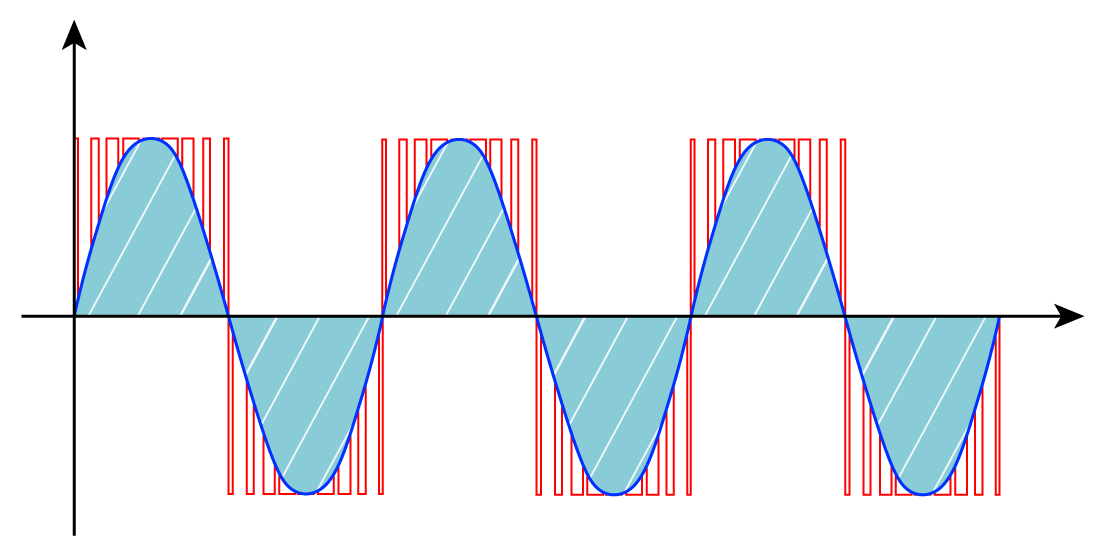

Electronic or variable fan speed controllers offer infinitely variable speed control for AC fans. They use phase angle control, Triac technology, to reduce the motor voltage, which is how they control fan speed. Triac fan speed controllers can control motors with motor currents of up to 10 A. These fan speed controllers are completely silent, because they reduce the mains voltage by cutting parts of it out. The remaining motor voltage will not have a perfect sinusoidal shape. Microprocessor control makes it possible to optimise the zero-cross detection. This means that the Triacs can be controlled more accurately, resulting in a quiet motor operation.

Nevertheless, depending on the motor type, some additional motor noise at low speed might occur due to the non-sinusoidal shape of the motor voltage. Increasing the minimum motor voltage will reduce the noise.

Low speed

Medium speed

High speed

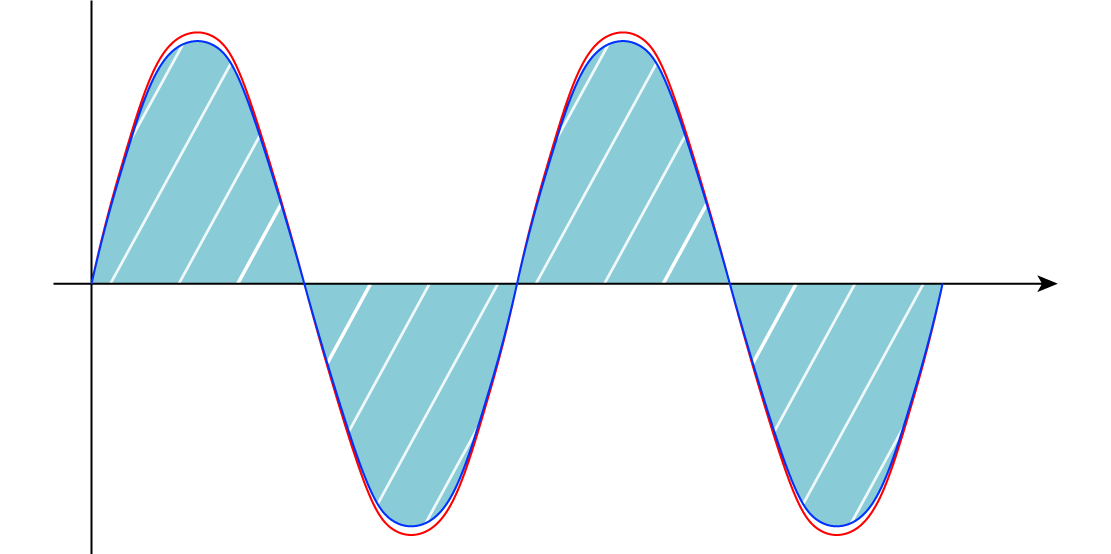

Low speed

Medium speed

High speed

Variable Speed Drive

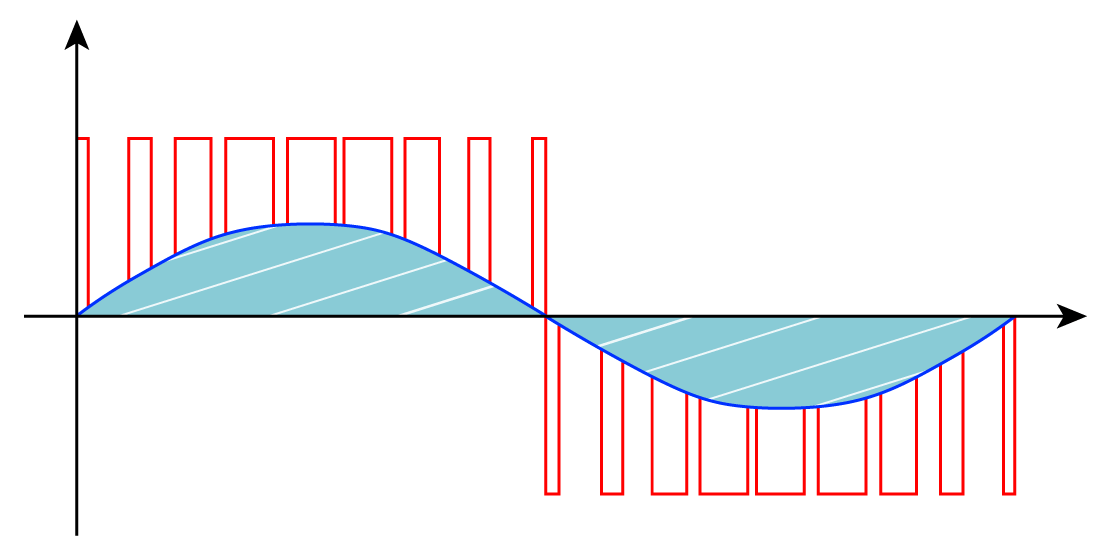

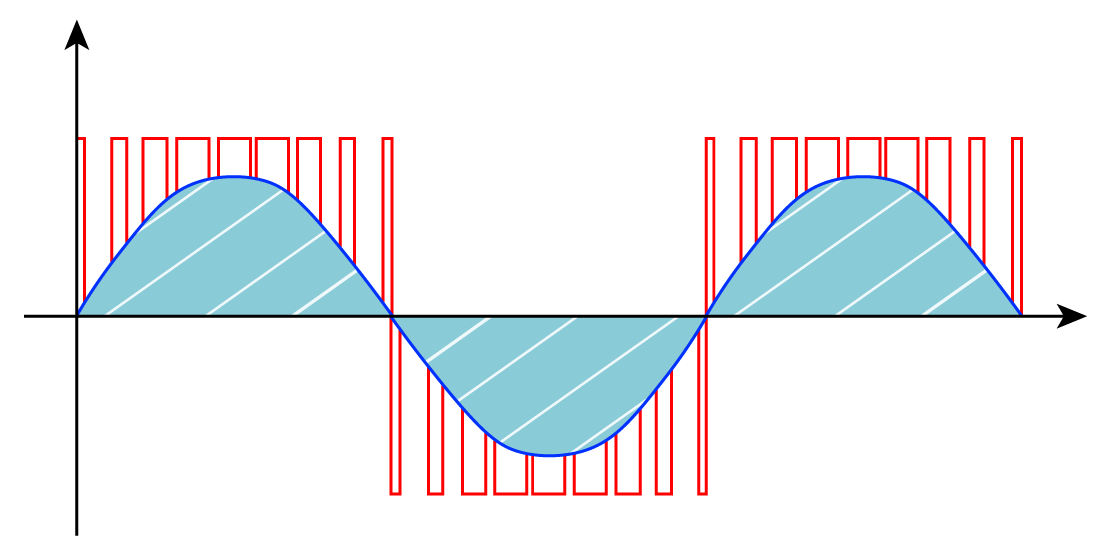

Frequency inverters, also called Variable Speed Drives, provide infinitely variable speed control for AC fans. The careful reader knows that the electronic fan speed controllers discussed above do too. So what is the difference? A frequency inverter uses Pulse Width Modulation (PWM), IGBT technology, to adjust the motor voltage and frequency. With PWM, there is an exceptionally quiet motor control in all circumstances and motor voltage that is almost perfectly sinusoidal. Depending on its settings, the frequency inverter itself can also operate very silently.

Because a frequency inverter switches from direct current to alternate current frequently, it can cause EMC pollution in other devices that are connected to the same power grid. To reduce this EMC pollution, (expensive) special filters were developed. A frequency inverter also has a high configuration cost relative to other fan speed controllers because of its inherent complexity. In a nutshell, frequency inverters are more expensive than electronic fan speed controllers, more complicated to configure, and may require some additional tools, but they offer very precise motor control. These speed controllers are very energy efficient and capable of controlling high motor currents.

The requested motor speed can be adjusted via the controls that are integrated onto the device itself (potentiometer or push buttons). It is also possible to adjust the motor speed remotely via Modbus RTU or an analog control signal.