EC fans

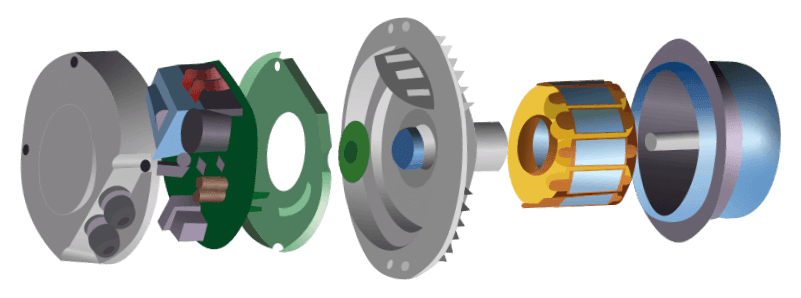

What is an EC Motor?

EC fans are fans with an EC motor. An EC (Electronically Commutated) motor typically has a rotor of permanent magnets which rotates in (or around) the stator. The built-in fan speed controller generates an electric current in the stator windings, which can be more or less powerful depending on the 0-10V control signal. The electric current generates a rotating magnetic field, which the permanent magnets follow. This is how an EC motor runs.

What are the benefits of an EC Motor?

The main advantages of EC motors over AC motors are:

- High energy efficiency

- A long service life

- Reduced noise

- Relatively low electromagnetic interference (EMI)

The difference in energy consumption between an AC and an EC motor is clearly visible at reduced speed. At 20% speed, energy savings of around 70% can be achieved when compared to an AC motor. At nominal speed, energy savings of around 10 % can be achieved.

The permanent magnets and the integrated electronics make this type of motor rather expensive. The higher purchase price is however compensated by its lower energy consumption.

How can we regulate EC Motor speed?

As opposed to an AC motor, the control electronics for the fan speed are always integrated in the EC motor. This is because the EC motor type requires coordination between the rotor position and motor currents. Without this coordination, starting up the motor would not be possible. The integrated fan speed controller is responsible for this coordination because it converts the AC voltage of the electrical network into the DC voltage that is required to control the motor.

An EC motor requires a control signal that specifies the requested fan speed. This control signal can be digital (Modbus RTU communication) or analog (typically 0-10 Volt). The control signal can be generated manually via a control switch (in steps) or via a potentiometer (stepless). It can also be generated by an HVAC sensor or an HVAC controller for demand-based fan speed control.

Manual fan speed control

If you want to control fan speed manually, the control signal can be generated via:

- Control switch - A control switch generates a 0-10 Volt signal in steps. With a control switch , a limited number of predefined fan speeds can be selected easily.

-

Potentiometer - This is a device to generate a continuously variable

0-10 V control signal. Potentiometers are available with or without OFF position. The control signal can be generated from high to low (10 – 0 V) or from low to high (0 – 10 V)

Demand based fan speed control

If you instead want to control fan speed automatically, the control signal can be generated via:

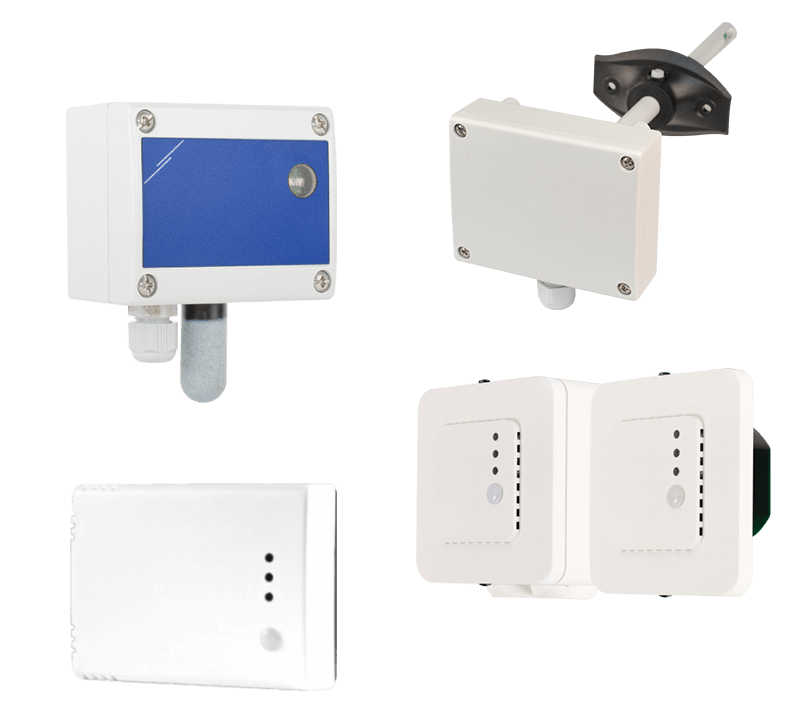

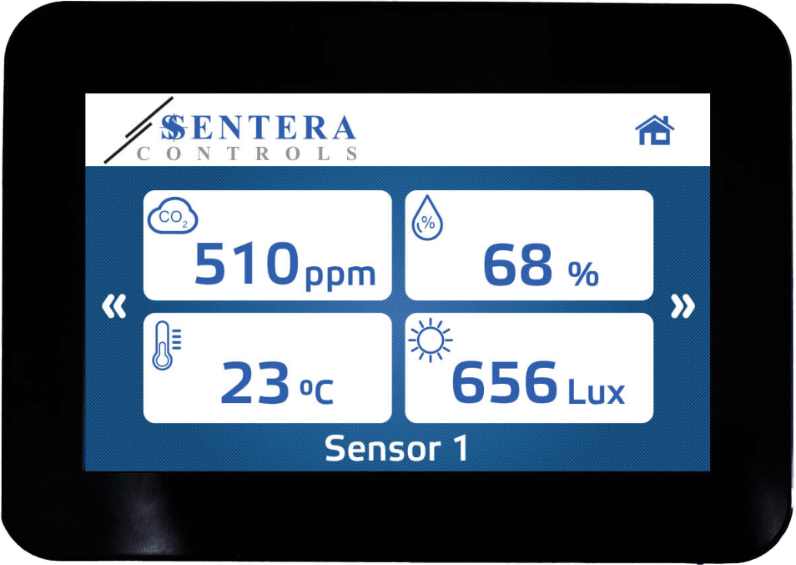

- Intelligent HVAC sensors - A standard HVAC sensor or HVAC transmitter measures certain, values like temperature, humidity, CO2, air quality, etc. These measured values are then transmitted to the motor via analog outputs or via Modbus RTU communication. Intelligent HVAC sensors have one output. The output value is determined by an intelligent algorithm. This way, the control signal continually reacts to keep one or more parameters within range. If, for example, CO2 or humidity levels are too high, an extraction fan can be ordered to go at higher speed. More information about air quality can be found on www.air-quality-monitor.eu.

- Control solutions for ventilation systems - To control a complete ventilation system, Heat Recuperation Unit or Air Handling Unit, it is often a good option to centrally control the EC motors in the system. Depending on the connected devices and software, this can be reasonably to very complex. This can be done both by a localized HVAC controllers, and remotely with an internet-accessible solution. Another benefit of HVAC control solutions is that they are made for a specific application. They are usually very user-friendly, intelligent and easy to install.