Why do we need to control fan speed?

A motor at full speed is noisy, consumes much energy, costs money, and exacerbates heat losses. If we decrease fan speed, the motor will make less noise, will consume less energy, and this will, in turn, reduce the operational costs of the ventilation system. All this serves to increase the comfort of residents.

Why would we not simply buy a smaller motor if that were the case? A motor needs to be at full capacity, like when there is a large crowd of people in a single room. A motor will also need to run faster when the temperature or relative humidity differs too greatly from the outdoors. In other words, to regulate the Indoor Air Quality, the motor and fan speeds need to be adjusted.

How does fan speed control impact air quality?

The benefits of ventilation for indoor air quality are almost self-evident. As a room is enclosed on all sides, and humans use the air in the room, the air quality will never remain the same as it is outside. In the past, we used windows to make sure fresh air reached us. This always had several issues, as in winter it is hard to balance good air quality with heat losses. In the industrial age, air pollution became another issue. The need for intelligent and energy-efficient ventilation control became apparent.

A modern ventilation system regulates the indoor air quality based on different parameters, such as temperature, relative humidity, CO2, and TVOC. These parameters change with the amount of people in one room, the outside temperature, and the usage of certain pollutants. When one of these parameters becomes too high, the fan speed will need to increase, to get more fresh air inside. How exactly this happens, you can read in the tab “technology”.

COVID-19 contamination via aerosols

The risk of becoming infected with the COVID-19 virus is higher in crowded and poorly ventilated spaces. Transmission of COVID-19 via aerosols rarely occurs outdoors or in enclosed spaces with a large volume. Most ventilation systems are dimensioned to provide crowded spaces with sufficient fresh air. When the room is not occupied, the air volume flow rate can be reduced while still supplying sufficient fresh air. However, some ventilation systems partially recover indoor air to minimise heat losses. This internal air circulation can spread viruses through the building. Therefore, the general recommendation is to deactivate indoor air recirculation, to increase the supply rate of fresh air and the extraction rate of stale air.

Energy savings

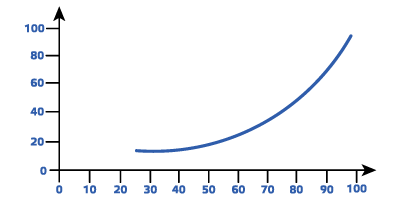

Another advantage of fan speed control is energy savings. If we would not control the fan speed, but instead let the motor run at full speed, there would certainly be a sufficient fresh air supply. But even a slight reduction in fan speed has a major impact on the electrical energy consumption of the fan. A typical HVAC fan follows a quadratic torque curve. Depending on the motor type, a reduction of 25 % air volume flow corresponds with 50 % less energy consumption. In addition, a lower air volume flow rate also results in a quieter operation.

Input power (%)

Flow rate (%)

Minimise heat losses

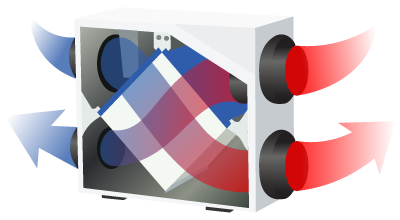

In colder and moderate climates, extracted warm indoor air is replaced by fresh air that can be much colder. That means that if we ventilate, we would need to spend more energy on heating. Modern ventilation systems are equipped with a heat exchanger to minimize such heat losses. Nevertheless, additional energy can be saved by reducing the fan speed when possible. By measuring the air quality of the indoor air, the fan speed can be continuously optimised while the indoor air quality is guaranteed.

Extended service life

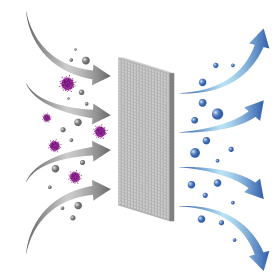

Air filters last longer when reducing the air volume flow rate. This is logical; the more air that passes through the filters, the higher the risk of contamination of the filters. A reduced air volume flow rate also has a positive effect on the service life of the mechanical parts of the fan. These prolonged service intervals reduce the operational costs and the total lifetime cost.

Increased comfort

Reduced risk for Covid-19 contaminations

Energy savings

Minimise heat losses

Extended service life

Optimal indoor air quality