What is a control signal?

Control signals are signals that control devices, usually remotely. We distinguish between digital and analog control signals. Although analog signals have been popular for many years, digital control signals have surged in popularity because of their inherent advantages. Their most prominent advantage is that they are reprogrammable.

Control signal type

Modbus communication to adjust fan speed

Digital communication (e.g. Modbus RTU or SenteraWeb) has many positive aspects. Cable lengths of up to 1.000 m are possible. Apart from transmitting the correct fan speed to the motor or fan speed controller, it has the possibility to receive information from other Modbus-compatible devices. Motor status, motor speed, motor temperature, and actual motor power are a few examples. Modbus-compatible devices can use digital communication to connect to SenteraWeb through the Sentera internet gateway. This universal online HVAC platform makes it possible for internet users to monitor connected HVAC devices, to adjust settings and to log data.

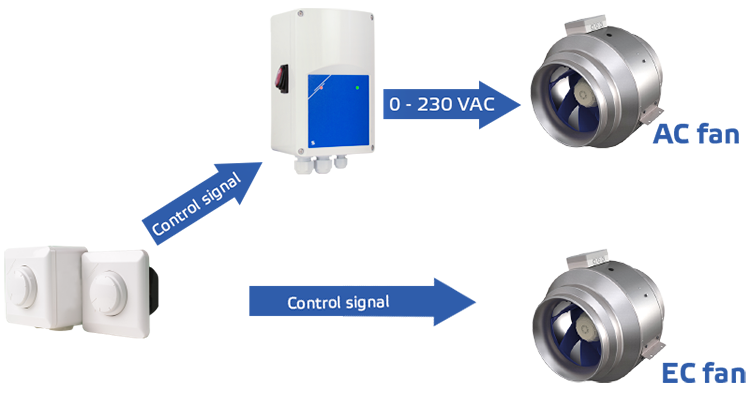

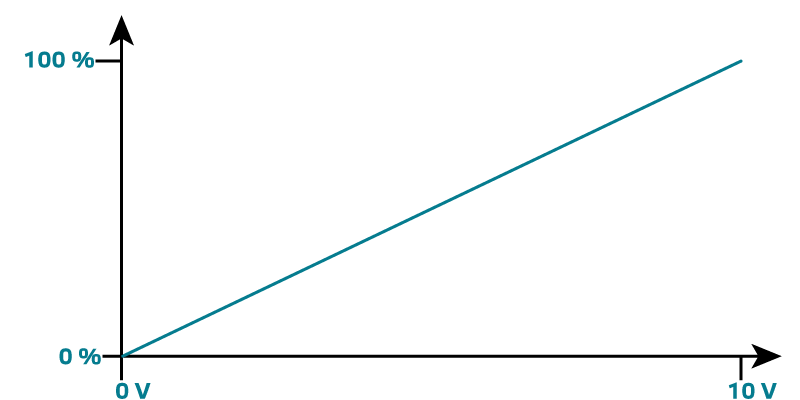

Analog control

Analog control signals have been used in the (home) automation industry for many years. The requested fan speed is transmitted to the EC fan or fan speed controller via a simple 0-10V signal. AC fans , as well as EC fans, can be controlled via a 0-10V signal. It is a simple technology and it usually works well if cable lengths remain limited. The exception is if the control lines are installed nearby power lines, because there is a risk of interferences. That is why it is advisable to limit the cable length of the analog control signal to 10 m and to use shielded cables to minimise the risk of interferences.

How to generate a control signal?

Control switches for 3-step fan speed control

Control switches generate a 0-10V signal in 3 steps. They are available with or without an OFF position. A stepped control signal means that there are 3 preset positions at which the motor should run. Their stepped 0-10V signal can be used to control EC fans, AC fan speed controllers, frequency inverters, etc. The exact values of positions 1 and 2 can be adjusted during installation with internal trimmers. Position 3 is equal to the supplied voltage – typically 10 VDC. If there is an OFF position, this corresponds to 0 VDC.

Potentiometers for variable fan speed control

A potentiometer, much like a control switch, generates a 0-10 V control signal. This control signal can be stepless or stepped and can thus be used for continuously variable EC fan speed control. It can also control a frequency inverter, an AC fan speed controller, etc. Other analogue control signals, e.g. 0-20 mA or a PWM signal, can also be generated. Potentiometers are available with different supply voltages and with or without OFF position.

HVAC sensors for demand based fan speed control

Intelligent HVAC sensors generate a 0-10V control signal based on measurements of air quality parameters. Based on these measurements, they directly control EC fan speed, AC fan speed controllers or frequency inverters. The fan speed is automatically controlled to keep temperature, relative humidity, CO2, TVOC or differential pressure within a preselected range. All parameters can be adjusted via Modbus RTU or SenteraWeb to ensure fan speed is optimal for its intended use under all possible circumstances.